French, ethical and consigned cosmetics

Products of nature

Observing nature and understanding it is one of the founding principles of oOlution.Organic farming is based on this same idea of understanding nature and limited human intervention. That is why all our producers are certified organic or are sustainably wild harvested.

A secret of manufacturing... For example, our poppy extract, found in Feet Good, is produced near Gap by an organic farmer. The Buriti oil in Oil Lala, Plump It or Beat It is wild picked. 70% of our ingredients are grown in France, for fresh ingredients that meet the strictest organic standards. For ingredients produced abroad, the same care is taken to ensure quality. This is the case, for example, for the coconut oil, which comes from a group of organic family farms in the Philippines.

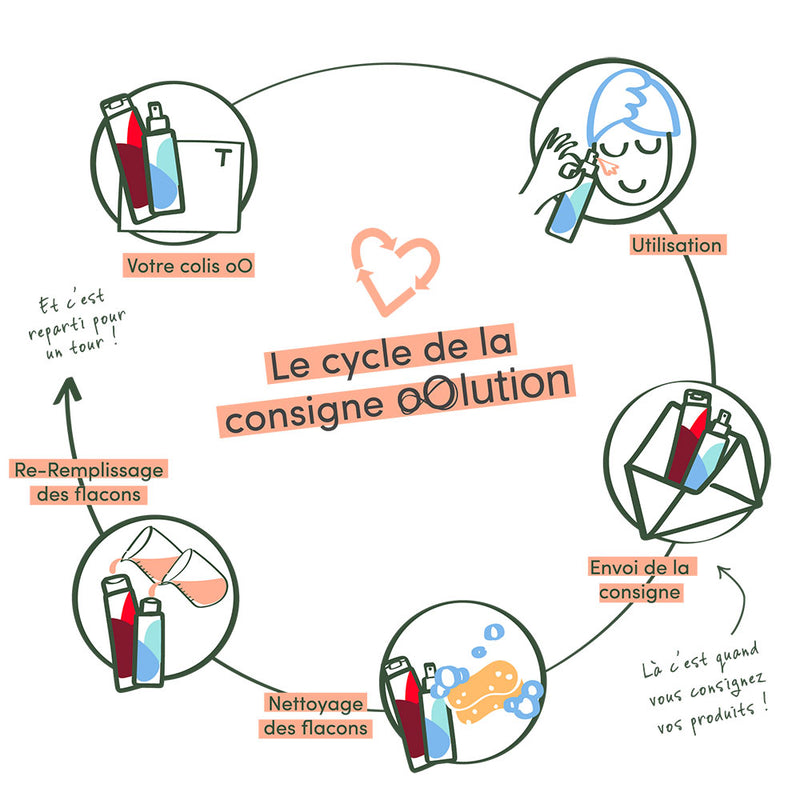

oOlution has implemented the deposit in 2019 so that every empty care can have a second life or be recycled. A T envelope is slipped into each order, once your skincare is empty, you can return it to us in the envelope. The containers are then sent to an ESAT centre where people with disabilities clean them so that they can receive a new treatment. Producing new containers requires raw material that we save by using those that can be reused. Returnable containers that cannot be reused are sent to TerraCycle to be recycled into garden furniture. With the deposit we have started a virtuous cycle and we want to extend it by offering a deposit box system at our retailers.

Working in collaboration with an ESAT is to participate in the professional integration of disabled people, this initiative has also developed since we now work with 3 centers. All the bottles and jars that are returned to us are sent to these centres to be washed and reused.

Non-reusable packaging, such as tubes for example, are sent to TerraCycle, a company specialised in upcycling waste. The waste is then diverted from landfill and incineration and transformed into useful objects (such as garden furniture). Who knows, you may be sitting on Gentle Angel tubes ;)

Returned glass bottles and jars

Recycled cleansers, body care containers

Returnable products

Centres

ESAT

oOlution is a B Corp

The B Corp Movement brings together companies committed to a common cause: transforming the global economy. We value a more inclusive, equitable and regenerative economy that benefits everyone.

We believe in a Company with a positive impact for all its stakeholders : shareholders, employees, communities, customers, and the living world of which we are all a part.

First cold pressing

All the vegetable oils and butters are organically produced and are extracted by first cold pressing. Cold pressing is the noblest method because it does not overheat the ingredient and therefore keeps all its benefits.

Distillation of essential oils and floral waters

All the essential oils present in our skin care products are also organically produced, as are the floral waters. They are carefully processed in order to preserve all their benefits and the diversity of their active ingredients. Steam distillation allows the extraction of essential oils and floral waters in the respect of the plants, at low pressure.

To bring the best to your skin, the manufacturing and extraction techniques are studied and chosen because they offer the best of the ingredients. Working the raw material cold is to ensure to keep all the active ingredients of the oils and plants. The soaps undergo the same treatment as the vegetable oils and are also worked cold. Cold saponification produces a soap superfatted that protects and nourishes your skin intensely.